Lead-Acid Battery Technology

A comprehensive guide to the most established energy storage technology powering industries worldwide

Construction and Working Principle

Lead-acid batteries represent one of the oldest and most reliable energy storage technologies, with applications ranging from automotive starting systems to large-scale energy storage solutions known as big battery installations. The basic construction of a lead-acid battery has remained relatively consistent since its invention in 1859, though modern advancements have significantly improved performance and durability.

A typical lead-acid battery consists of multiple electrochemical cells connected in series. Each cell contains two types of electrodes: the positive plate made of lead dioxide (PbO₂) and the negative plate composed of spongy lead (Pb). These plates are immersed in an electrolyte solution consisting primarily of sulfuric acid (H₂SO₄) diluted in water.

The plates are separated by insulators known as separators, which prevent direct contact between positive and negative plates while allowing ion flow. In modern batteries, these separators are usually made of porous materials like polyethylene or glass fiber. The entire assembly is contained within a hard plastic case, typically polypropylene, which is both durable and resistant to the corrosive electrolyte.

The working principle of a lead-acid battery is based on reversible electrochemical reactions. During discharge, when the battery is supplying power, the following chemical reactions occur:

- At the negative plate: Pb + HSO₄⁻ → PbSO₄ + H⁺ + 2e⁻

- At the positive plate: PbO₂ + HSO₄⁻ + 3H⁺ + 2e⁻ → PbSO₄ + 2H₂O

- Overall reaction: Pb + PbO₂ + 2H₂SO₄ → 2PbSO₄ + 2H₂O

These reactions produce an electrical current as electrons flow from the negative plate to the positive plate through an external circuit. During this process, both plates become coated with lead sulfate (PbSO₄), and the sulfuric acid is consumed, reducing the electrolyte's specific gravity.

Charging reverses these reactions, restoring the active materials on the plates and the concentration of sulfuric acid in the electrolyte. This reversibility is what makes lead-acid batteries rechargeable and suitable for applications requiring repeated cycles of discharge and charge, including the demanding requirements of a big battery system.

The standard nominal voltage for a single lead-acid cell is 2.0 volts. Most batteries combine six cells in series to produce a 12-volt battery, which has become the standard for automotive applications. However, big battery installations may consist of hundreds or thousands of cells connected in series and parallel configurations to achieve the required voltage and capacity.

Lead-Acid Battery Structure

Battery Case

Durable polypropylene container housing all components

Positive Plates

Lead dioxide (PbO₂) coated grids serving as cathode

Negative Plates

Spongy lead (Pb) coated grids serving as anode

Separators

Porous insulators preventing short circuits between plates

Electrolyte

Sulfuric acid (H₂SO₄) and water solution facilitating ion flow

Charge-Discharge Cycle

Key Materials and Technologies

The performance, durability, and cost-effectiveness of lead-acid batteries depend critically on the materials used in their construction and the technologies employed in their manufacturing. These components have evolved significantly over time, enabling lead-acid batteries to remain competitive even as newer technologies emerge, especially in big battery applications where cost and reliability are paramount.

Lead Alloys

The grid structures that form the backbone of battery plates are typically made from lead alloys rather than pure lead, which is too soft and weak for this purpose. The choice of alloy significantly impacts battery performance:

- Lead-Calcium Alloys: Most common in maintenance-free batteries, these alloys reduce water loss through gassing, enabling sealed designs. They offer good corrosion resistance but have higher internal resistance.

- Lead-Antimony Alloys: Provide stronger grids with better conductivity and mechanical strength. More common in flooded batteries requiring periodic maintenance. Antimony content ranges from 1-12% depending on application.

- Lead-Selenium Alloys: Offer improved cycle life and charge acceptance compared to traditional antimony alloys, often used in deep-cycle applications.

- Lead-Tin Alloys: Enhance grid strength and corrosion resistance, frequently used in premium batteries and big battery systems requiring extended service life.

Active Materials

The active materials coating the grids are responsible for the electrochemical reactions:

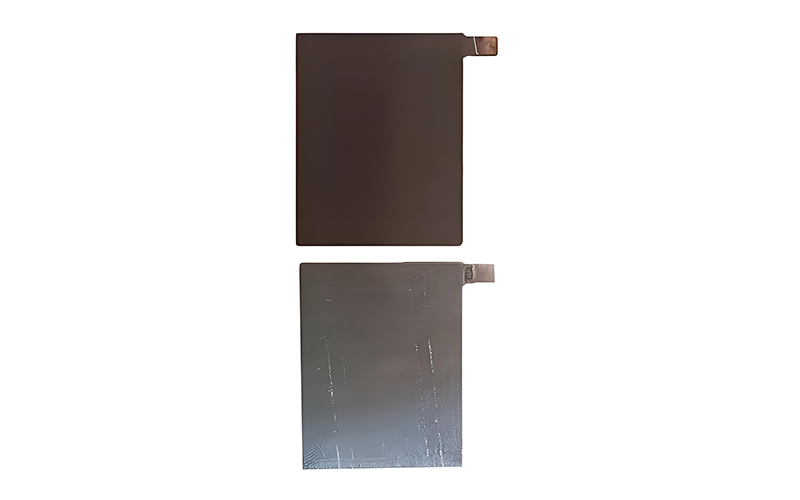

- Lead Dioxide (PbO₂): Used on positive plates, this dark brown material serves as the cathode during discharge. Its crystalline structure and porosity significantly affect capacity and cycle life.

- Spongy Lead (Pb): Applied to negative plates, this porous, sponge-like lead structure serves as the anode during discharge. Its surface area and structure influence charge acceptance.

- Sulfuric Acid (H₂SO₄): The electrolyte provides the ions necessary for the electrochemical reactions. Its concentration (typically 37-40% by weight) affects battery performance and freezing point.

Separator Technologies

Separators play a critical role in preventing short circuits while allowing ion flow. Modern separator technologies include:

- Micro-porous Rubber: Traditional material offering good chemical resistance but limited porosity.

- Polyethylene (PE) Separators: Lightweight with excellent chemical resistance and uniform porosity.

- Glass Mat Separators: Used in VRLA (Valve-Regulated Lead-Acid) batteries, these absorb and immobilize the electrolyte while providing excellent ion conductivity.

- Composite Separators: Combine materials to optimize properties like porosity, strength, and resistance to dendrite growth.

Advanced Technologies

Recent innovations have enhanced lead-acid battery performance:

- Absorbent Glass Mat (AGM): Immobilizes electrolyte in a fiberglass mat, enabling sealed, maintenance-free operation with improved cycle life.

- Gelled Electrolyte (Gel Cells): Uses silica to gel the electrolyte, preventing spillage and enabling operation in any orientation.

- Carbon-Enhanced Negative Plates: Adding carbon to negative plates improves charge acceptance and cycle life, making them suitable for renewable energy storage in big battery applications.

- UltraBattery™ Technology: Combines a lead-acid battery with a supercapacitor in a single cell, providing excellent power performance and cycle life for hybrid applications.

These material advancements and technological innovations have enabled lead-acid batteries to maintain their position in various markets, from automotive starting systems to large-scale energy storage, where the big battery installations benefit from their low cost, high reliability, and mature manufacturing infrastructure.

Battery Plate Materials

The microstructure of active materials directly impacts battery performance characteristics like capacity, charge acceptance, and cycle life.

Material Composition Comparison

Separator Technology Evolution

1950s: Rubber Separators

First commercial separators with limited performance

1970s: Polyethylene Separators

Improved porosity and chemical resistance

1980s: Glass Mat Technology

Enabled sealed, maintenance-free batteries

2000s: Composite Separators

Optimized performance for big battery applications

Manufacturing Process

The manufacturing of lead-acid batteries is a sophisticated process that combines precision engineering with careful material handling to produce reliable energy storage devices. From raw material preparation to final testing, each step must be executed with strict quality controls to ensure performance consistency, especially for large-scale big battery applications where reliability is critical.

1. Raw Material Preparation

The process begins with the preparation of raw materials:

- Lead Smelting and Alloying: Primary or recycled lead is melted and alloyed with other metals (calcium, antimony, tin, etc.) according to precise formulations. The molten alloy is cast into ingots for subsequent processing.

- Lead Oxide Production: Metallic lead is converted into lead oxides (primarily lead monoxide, PbO) using either the Barton pot process or the ball mill process. This oxide will form the basis of the active materials.

- Separator Manufacturing: Depending on the type, separators are produced from polyethylene, glass fiber, or other materials using extrusion, calendaring, or mat-forming processes.

- Plastic Component Production: Battery cases, covers, and other plastic parts are injection-molded from polypropylene resin.

2. Grid Production

The grid serves as the structural framework for the battery plates and conducts electrical current:

- Casting: Molten lead alloy is poured into molds to form grid structures. Modern facilities use high-pressure casting machines for precise, consistent grid production.

- Expanding: Alternative to casting, this process involves slitting and stretching lead alloy sheets to create grid structures with uniform openings.

- Grid Treatment: Grids undergo cleaning and surface treatment to ensure proper adhesion of active materials.

3. Paste Preparation and Application

Active materials are applied to the grids in a paste form:

- Paste Mixing: Lead oxide is mixed with sulfuric acid, water, and additives to form a paste. The composition varies for positive and negative plates.

- Pasting: The paste is applied to the grids using automated pasting machines, ensuring uniform distribution and proper adhesion.

- Curing and Drying: Pasted plates are cured in controlled humidity and temperature environments to convert the paste into stable lead compounds and remove moisture.

4. Plate Formation

This electrochemical process converts the cured paste into active materials:

- Tank Formation: Plates are immersed in sulfuric acid solution and subjected to an electrical current. For positive plates, this converts lead oxide to lead dioxide (PbO₂); for negative plates, it forms spongy lead (Pb).

- Washing and Drying: Formed plates are thoroughly washed to remove excess acid and then dried.

5. Battery Assembly

Individual components are assembled into complete battery cells and batteries:

- Plate Stacking: Positive and negative plates are alternated with separators between them to form plate groups.

- Plate Group Welding: Plates of the same polarity are connected using lead straps, typically welded using ultrasonic or flame welding techniques.

- Insertion into Cases: Plate groups are inserted into battery case compartments.

- Intercell Connection: Cells are connected in series using lead connectors to achieve the desired voltage.

- Cover Sealing: Battery covers are sealed to the cases using heat sealing, adhesives, or mechanical fasteners.

6. Filling, Formation, and Finishing

The final steps complete the battery production process:

- Electrolyte Filling: For flooded batteries, sulfuric acid of specific gravity is added. For VRLA batteries, electrolyte is added and absorbed by separators before sealing.

- Final Formation Charge: Batteries undergo an initial charge to ensure all active materials are in their proper chemical state.

- Testing: Each battery is tested for voltage, capacity, and leakage. Big battery components undergo additional rigorous testing.

- Charging and Discharging: Batteries receive a conditioning charge and may undergo a formation cycle to stabilize performance.

- Labeling and Packaging: Approved batteries are labeled, cleaned, and prepared for shipping.

Modern lead-acid battery manufacturing facilities employ advanced automation and quality control systems to ensure consistency and performance. Environmental controls are strictly implemented to manage lead exposure and waste, with recycling programs that capture nearly all production scrap for reuse in the manufacturing process.

Manufacturing Process Flow

The production of lead-acid batteries involves multiple stages requiring precision control and quality assurance.

Raw Material Preparation

Grid Production

Paste Application & Curing

Plate Formation

Battery Assembly

Filling, Testing & Finishing

Quality Control Checkpoints

- Alloy composition verification

- Paste density measurement

- Curing temperature monitoring

- Weld strength testing

- Electrolyte specific gravity

- Voltage and capacity testing

- Leakage inspection

Production Statistics

Environmental Controls

Modern manufacturing facilities implement strict environmental protection measures:

Resource Recycling

Lead-acid battery recycling is one of the most successful and established recycling programs in the world, with recovery rates exceeding 95% in many countries. This high recycling efficiency not only conserves valuable resources but also prevents environmental contamination from lead, making it a model for sustainability in the battery industry. The recycling process is particularly important for big battery installations due to their large size and material content.

1. Collection and Transportation

The recycling process begins with the proper collection of used batteries:

- Collection Networks: Used batteries are collected through various channels including automotive service centers, retailers, and dedicated recycling drop-off points. Many jurisdictions have regulations requiring proper disposal of lead-acid batteries.

- Transportation: Batteries are transported in specialized containers that prevent leakage and damage. Regulations govern the transportation of lead-acid batteries as hazardous materials.

- Tracking Systems: Many regions implement tracking systems to ensure batteries reach authorized recycling facilities rather than being illegally dumped.

2. Breaking and Separation

At the recycling facility, batteries undergo initial processing to separate components:

- Breaking: Batteries are crushed in specialized machines that break the case and separate components without releasing hazardous materials.

- Material Separation: The crushed material is separated into three primary components:

- Lead-containing materials (grids, poles, and lead paste)

- Plastic (battery cases and covers)

- Electrolyte (sulfuric acid solution)

- Electrolyte Handling: Sulfuric acid is either neutralized to form water and a sulfate salt or purified for reuse in new batteries.

3. Lead Recycling

Lead recovery is the most valuable aspect of lead-acid battery recycling:

- Smelting: Lead materials are smelted in furnaces to separate pure lead from other metals and impurities. Different processes are used for metallic lead (grids, poles) and lead paste.

- Refining: Smelted lead undergoes further refining to remove remaining impurities, resulting in high-purity lead (99.99%+ purity) suitable for battery production.

- Alloy Production: Recycled lead is alloyed with other metals (calcium, antimony, etc.) to produce the specific alloys needed for new battery grids.

4. Plastic Recycling

Battery plastic components are also recycled:

- Washing and Purification: Plastic pieces are thoroughly washed to remove any remaining electrolyte or debris.

- Melting and Pelletizing: Clean plastic is melted and formed into pellets, which are then used to manufacture new battery cases and other plastic components.

- Quality Control: Recycled plastic pellets undergo testing to ensure they meet the required specifications for strength and chemical resistance.

5. Environmental and Economic Benefits

Lead-acid battery recycling provides significant environmental and economic advantages:

- Resource Conservation: Recycling saves up to 80-90% of the energy required to produce lead from raw ore. A typical 12-volt battery contains about 6-8 kg of lead that can be recycled.

- Pollution Prevention: Proper recycling prevents lead contamination of soil and water. One battery can contaminate up to 20,000 gallons of water.

- Economic Value: The recycling industry creates jobs and reduces reliance on mined lead. The recycled lead from batteries is often cheaper and more readily available than primary lead.

- Circular Economy: Lead-acid batteries create a closed-loop system where nearly 100% of materials can be recycled into new batteries. This circular model is particularly efficient for big battery systems where material volumes are substantial.

6. Regulatory Framework

Lead-acid battery recycling is governed by strict regulations worldwide:

- Collection Mandates: Many countries require retailers to accept used batteries when selling new ones (take-back programs).

- Processing Standards: Regulations specify proper handling, processing, and emissions controls for recycling facilities.

- Transportation Rules: International and national regulations govern the transport of used batteries as hazardous materials.

- Recycling Targets: Some jurisdictions establish minimum recycling rates to ensure high recovery of materials.

The high recycling rate of lead-acid batteries sets them apart from many other battery chemistries and contributes to their sustainability profile. As the demand for energy storage continues to grow, especially in big battery applications for renewable energy integration and grid storage, the well-established recycling infrastructure for lead-acid batteries remains a significant advantage for this mature technology.

Recycling Process Overview

Lead-acid batteries have one of the highest recycling rates of any consumer product, with over 95% of materials recovered.

Material Recovery Rates

Environmental Impact Comparison

Recycling vs. primary production of lead for batteries: